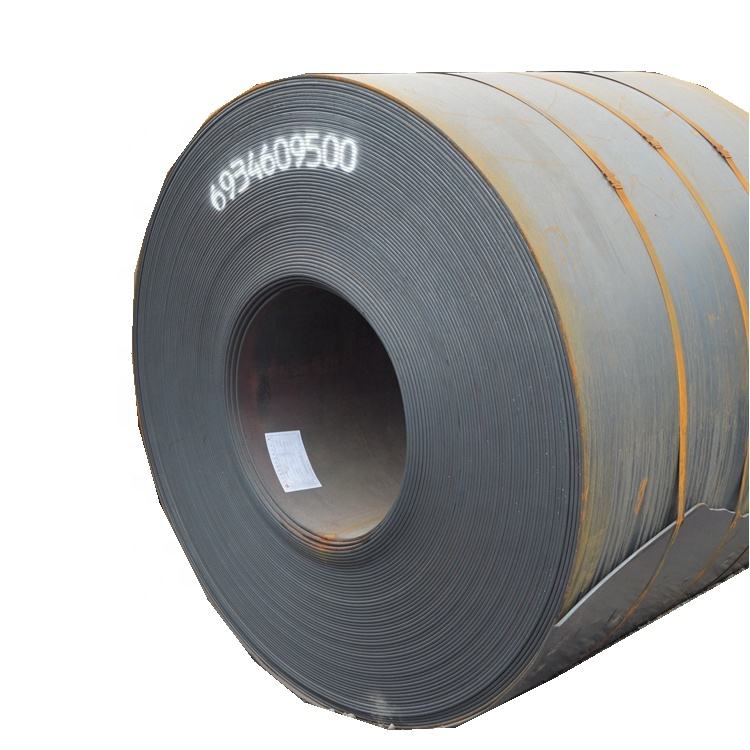

Ss400, Q235, Q345 Sphc Black Steel Carbon Coil Coil Iron Steel Metal Hr Hot Rolled Steel Coil

Hot-rolled steet/coil ho tloha ho qeta ho qetela chesang tšepe hlobolisa leloala tsoa ka laminar phallo tsidifatso ho mocheso set, e nang le winder coil, tšepe coil ka mor'a hore tsidifatso, ho ea ka litlhoko tse fapaneng tsa basebedisi ba, le fapaneng finishing line (flat. , ho otlolla, ho pota-pota kapa ho itšeha ka longitudinal, ho hlahloba, ho bekha, ho paka le logo, joalo-joalo) 'me e be poleiti ea tšepe, moqolo o bataletseng le lihlahisoa tsa tšepe tsa longitudinal ho itšeha.Hobane lihlahisoa tsa tšepe tse chesang tse chesang li na le matla a phahameng, boima bo botle, ts'ebetso e bonolo le weldability e ntle le thepa e meng e babatsehang, e sebelisoa haholo ho haha likepe, likoloi, borokho, kaho, mechine, sekepe sa khatello le liindasteri tse ling tsa tlhahiso.

| Kereiti | Boemo | Sebopeho sa Likhemikhale(%) | ||||

| Q215 | C | Mn | Si | S | P | |

| A | 0.09~0.15 | 0.25~0,55 | ≤0.3 | ≤0.05 | ≤0.045 | |

| B | ≤0.045 | |||||

| Q235 | A | 0.14~0.22 | 0.30~0,65 | ≤0.3 | ≤0.05 | ≤0.045 |

| B | 0.12~0.20 | 0.30~0,70 | ≤0.045 | |||

| C | ≤0.18 | 0.35~0,80 | - | ≤0.04 | ≤0.04 | |

| D | ≤0.17 | ≤0.035 | ≤0.035 | |||

| Q255 | A | 0.18~0.28 | 0.40~0,70 | ≤0.3 | ≤0.05 | ≤0.045 |

| B | ≤0.045 | |||||

| Q275 | 0.28~0.38 | 0.50~0,80 | ≤0.35 | ≤0.05 | ≤0.045 | |

Carbon steel ke mofuta o tloaelehileng oa tšepe eo e leng motsoako oa tšepe le carbon.E na le khabone e phahameng, sebaka se tlase sa ho qhibiliha le ho tšoarella ho hoholo ha ho bapisoa le tšepe e sa hloekang.

Carbon steel ke thepa ea boenjiniere le ea kaho e sebelisoang haholo ho fetisisa bakeng sa lits'ebetso tsa indasteri ka bongata bo boholo, ho kenyeletsoa meaho ea leoatle, limela tsa motlakase, lipalangoang, ts'ebetso ea lik'hemik'hale le tlhahiso ea peterole le ho hloekisoa.

Δ Thepa e chesitsoeng e kenngoa ka seboping se batang se kolobisitsoeng le ka mor'a ho tšela asiti.

Δ Lirolo tsohle tsa leloala li siloa mochining o nepahetseng oa ho sila o nang le chamfering e nepahetseng kamora ts'ebetso ea pele ea ts'ebetso.

Δ Lishiti tsohle li tšeloa ka har'a litanka tse fapaneng 'me maqephe a omisitsoe mochining oa brashi pele o romelloa.

Δ Lishiti tsena li boetse li annealing ebe li romelloa ho otlolla mochini bakeng sa ho otlolla le ho kha ka asiti le ho romelloa ho paka ho latela boholo le boleng.

Δ Ho hlahlojoa ho etsoa ka mekhahlelo e fapaneng.Ke basebetsi ba nang le boiphihlelo ba ho boloka taolo e nepahetseng ka kakaretso ea ts'ebetso ea kahare ka ho roala, ho hula, ho khetha, ho phekola litšila joalo-joalo.